Main Header

Site Search

Biogen Idec Data Center

Comprehensive Energy Analysis and Data Center Upgrades

Energy usage in Biogen Idec’s Data Center in Cambridge, MA was significantly reduced with a zero-impact solution, implemented by ENGIE Services U.S. (ENGIE). The solution cut energy costs, corrected system malfunctions, and provided Biogen Idec with a high level of working knowledge and control over HVAC operations.

The Partnership

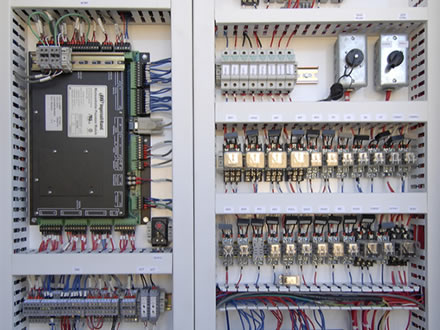

The data center energy efficiency solution helped alleviate a short-circuiting problem, which was occurring with increasing frequency, stemming from gaps in between and under racks, as well as hot air in cold aisles and at the end of aisles. Additionally, Computer Room Air Conditioner (CRAC) units were running constantly, independently and with a low level of control or information about their operation, making them highly inefficient. Lastly, cold air beneath the raised floor was obstructed by wires and piping, contributing to the hot spots found in cold aisles. ENGIE’s solutions helped to alleviate hot and cold spots throughout the facility.

3 Dimensions of Impact

ENGIE is committed to building three dimensions of impact in every customer’s future:

- Supporting People

- Training and education of personnel increased understanding and control over the hospital physical plant systems.

- Enabled personnel to dynamically respond to CRAC unit failures and temperature changes in the room, with central control unit monitors, air-movers, and sensors.

- Saving Money

- The project resulted in a total annual savings exceeding $60,000.

- More than $53,200 in NStar Utility Incentives helped offset project construction costs.

- Protecting the Environment

- Variable speed fans with flex duct moved air directly from the hot aisle to the CRAC units making the CRAC units more efficient.

- Fan trays with eight variable speed fans were placed strategically in cold aisles to pull air to racks, causing the air to move much more efficiently.

- Improvements resulted in annual electricity savings of 387,327 kWh, which is equivalent to removing 62 cars from the road for an entire year.