ENGIE Services U.S has a new home online with ENGIE North America.

For the latest information about how we're helping to shape the transition to a carbon-netral economy, visit us at our new pages:

Main Header

Site Search

Harvard Pilgrim Health Care Data Center

Massachusetts

Comprehensive Energy Efficiency Treatment

ENGIE Services U.S. (ENGIE) performed a comprehensive energy analysis for Harvard Pilgrim Health Care, one of the country’s leading health insurance plan providers.The Partnership

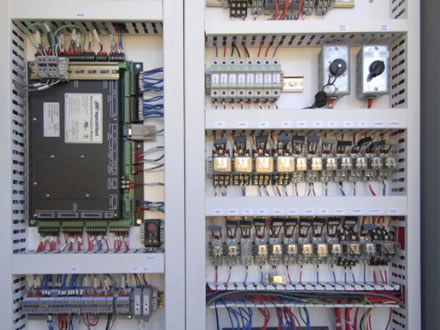

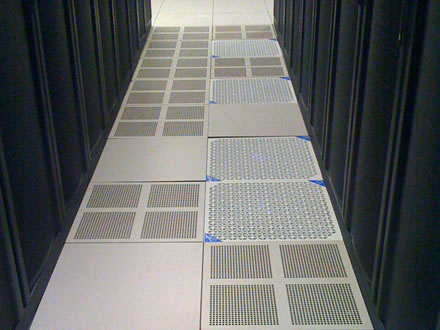

The ENGIE data center engineering team worked closely with Harvard Pilgrim Health Care to maximize efficiency in the unique design parameters of their 2,500 sq. ft. data center in Quincy, Massachusetts. The data center is split between a raised floor area of approximately 2,500 sq. ft. and a solid floor area of around 1,500 sq. ft. ENGIE performed several upgrades to make the air distribution in the room as efficient as possible. Elimination of cold and hot air streams mixing together was solved by the installation of blanking panels and air dams. Since the control room of the data center was also situated above the same raised floor plenum that is used for cold air supply, it was walled off to increase the pressure and thermal efficiency under the floor.3 Dimensions of Impact

ENGIE is committed to building three dimensions of impact in every customer’s future:

- Supporting People

- The central control system implemented to manage the CRAC units, floor panels, overhead air movers and temperature sensors in the rooms, allows the data center managers to look at real-time data from the rooms, including temperatures in the cold aisles, fan speeds, status of equipment as well as alerting them via email of any thermal issues in the room. In addition, the system responds to severe temperature changes in zones or CRAC failures by automatically turning on additional CRACs and adjusting the speed of the fans to help the particular zone in trouble.

- Saving Money

- ENGIE qualified the project for nearly $100,000 in incentives, for an impressive simple payback period of 1.3 years. Air distribution upgrades and a central control system installation resulted in annual savings in excess of $80,000.

- Protecting the Environment

- The combined energy efficiency measures are saving 505,715 kWh annually, a significant reduction in the energy-intensive data center’s carbon footprint.

Integrated Program Highlights

Custom-designed solutions and services are critical to achieve Energy Effective™ facilities. To learn more about this integrated program, download the PDF to read the full technical scope.