Main Header

Site Search

Colonnade Hotel

Comprehensive Energy Efficiency Treatment

ENGIE Services U.S. (ENGIE) provided a comprehensive energy conservation analysis of the Colonnade Hotel in Boston, Massachusetts, a beloved Back Bay landmark, opened in 1971. ENGIE identified and implemented cost effective controls, lighting, chillers, and electrically commutated motor (ECM) technologies, saving the Hotel a quarter million dollars each year.

The Partnership

The Druker companies, and owner Ronald Druker, whose grandfather built the hotel, partnered with ENGIE to develop a comprehensive energy efficiency plan, emphasizing guest comfort and environmental sustainability. The project achieved impressive financial results, with a simple payback period of 2.3 years, an ROI of 43.8%, and an annual energy savings of over $250,000. ENGIE installed energy efficient lighting throughout the hotel including offices, the kitchen, and the parking garage. LED technology was installed in guest bathrooms, ballrooms, and restaurant and lobby areas. In office areas around the hotel, occupancy sensors were installed to further decrease energy usage by switching off lights in unoccupied areas.

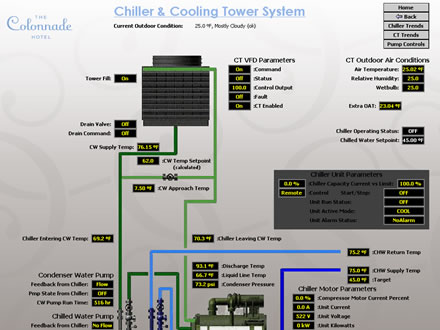

The existing Building Automation System (BAS) was replaced with a new system, complete with a computer-based front end with user-friendly interface for all the equipment tied to the existing BAS. The new BAS strategies included scheduling, set-back and optimum start/stop controls. The Colonnade’s Huntington Ballroom’s air handling units (AHU) were modified to accept return air. BAS controls were installed on the AHU’s existing outside air dampers and new return air dampers. Additionally, the BAS was programmed to set back these AHUs during unoccupied hours and to modulate the dampers to maintain room temperatures.

ENGIE replaced two of the existing water-cooled chillers with one 250-ton frictionless centrifugal chiller. Additionally, a refrigerant monitoring system, exhaust fan system, and automated control damper were installed to provide fresh supply air to the mechanical room.

3 Dimensions of Impact

ENGIE is committed to building three dimensions of impact in every customer’s future:

- Supporting People

- In the Colonnade’s 285 guest rooms and throughout the hallways, ENGIE replaced standard-efficiency motors in the fan coil units with ECM which use high-efficiency programmable brushless direct current (DC) motors. A new motor control card was installed in the fan coils that appropriately interfaces with the room temperature control system. This improved guest and staff comfort and allowed for precise individual thermal control over each hotel room.

- Saving Money

- ENGIE’s team garnered nearly $500,000 in incentives. The Colonnade Hotel saves over $255,00 annually as a result of the upgrades.

- Protecting the Environment

- The Colonnade Hotel illustrates its commitment to sustainability by achieving significant electricity gas savings.