ENGIE Services U.S has a new home online with ENGIE North America.

For the latest information about how we're helping to shape the transition to a carbon-netral economy, visit us at our new pages:

Main Header

Site Search

EF Education Center

Massachusetts

Comprehensive Energy Efficiency Treatment

EF Education First, a company that provides educational travel and cultural exchange programs throughout the world, was experiencing unmanageable energy costs at its 200,000 sq. ft. headquarters building in Cambridge MA. EF was also having difficulty maintaining thermal comfort in the relatively new building. The issue was escalating as EF’s business was expanding and the employee head count was increasing.ENGIE Services U.S. (ENGIE) performed a comprehensive energy efficiency treatment, which resulted in the designation of “Energy Project of the Year” by the Association of Energy Engineers.

The Partnership

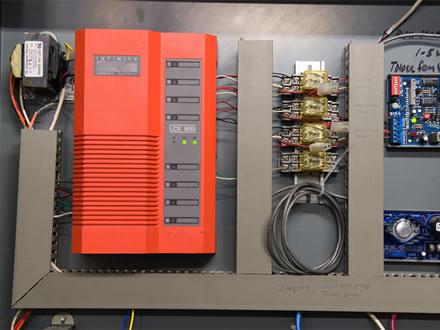

The existing systems consisted of air handling units (AHU) on each floor equipped with direct expansion (DX) cooling coils and compressors that reject heat to a condenser water loop/cooling tower system. The ENGIE upgrade consisted of converting the DX cooling to central plant chilled water cooling by changing out the AHU DX coils to chilled water coils, converting the condenser loop piping to chilled water piping, and adding two efficient variable frequency drive (VFD) 300-ton centrifugal chillers to the system. Other changes included the installation of electronically commutated motors (ECM) in place of the inefficient fractional horsepower motors in the 250 fan-powered boxes throughout the building, Building Automation System (BAS) upgrades, and VFD installations on pumps and fans. Ventilation was controlled through the use of a building-wide CO2 monitoring system and the addition of restaurant hood controls that reduced exhaust and makeup air during periods when the grills and ovens weren’t being used. With the new HVAC systems and free cooling controls, for the first time in the life of the building, temperatures were maintained in the comfort zone without mechanical cooling.3 Dimensions of Impact

ENGIE is committed to building three dimensions of impact in every customer’s future:- Supporting People

- The upgrades also solved a number of comfort and operational issues – systems were balanced, appropriate ventilation was provided to each space and hot spots/cold spots were eliminated.

- Saving Money

- ENGIE qualified the projects for $600,000 of NSTAR incentives.

- Protecting the Environment

- The energy savings provided a significant reduction in pollutants from reduced gas and electricity use.

Integrated Program Highlights

Custom-designed solutions and services are critical to achieve Energy Effective™ facilities. To learn more about this integrated program, download the PDF to read the full technical scope.